Manufacturing & Sales of Automation Equipment

We have been developing and manufacturing automation equipment for the production of SONY products for around two decades,

and based on the know-how gained over the years, we have developed and supplied automated production equipment for headphones,

optical devices, miniaturized semiconductors, mobile phone displays, and beam projectors to SONY factories around the world.

In recent years, we have also been actively manufacturing and selling customized automation equipment for Chinese, Singapore,

and Korean manufacturers outside the SONY Group. In particular, the Image Processing Vision System, Process Monitoring Software,

and Forecasting and Management System that we have developed for smart factory construction are contributing

to the improvement of productivity and stringent quality control of our customers.

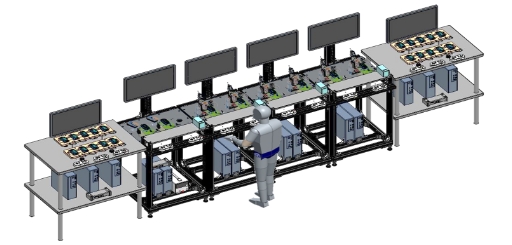

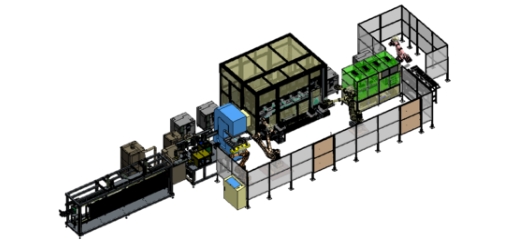

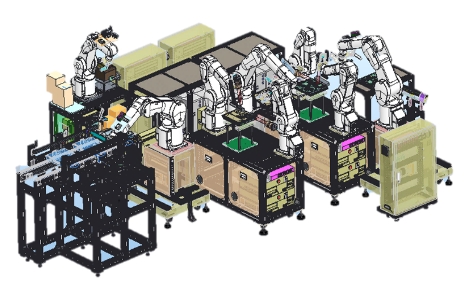

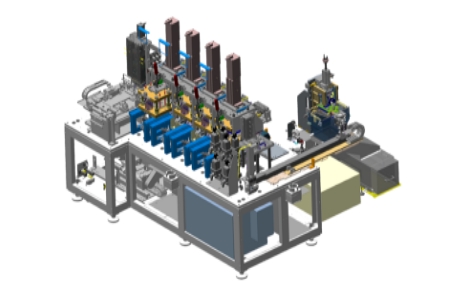

On-demand automatic assembly/inspection line

-

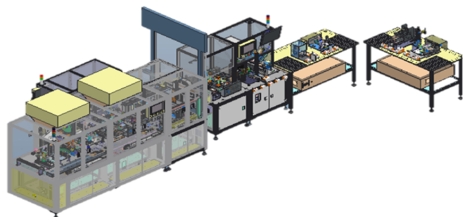

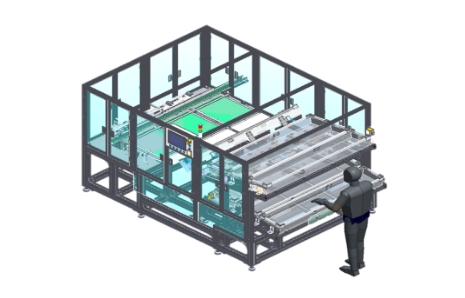

Electronics Pre-Adjustment

& Inspection Equipment

-

Equipment configuration

- : Assembly -> Firmware Record -> Performance Test

-

Specification

- - Equipment Cycle Time : 15sec

-

-

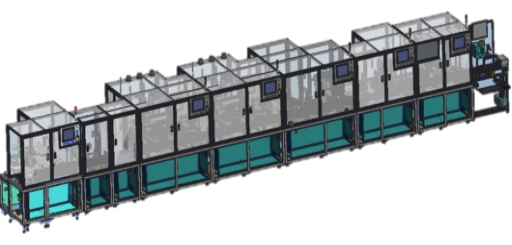

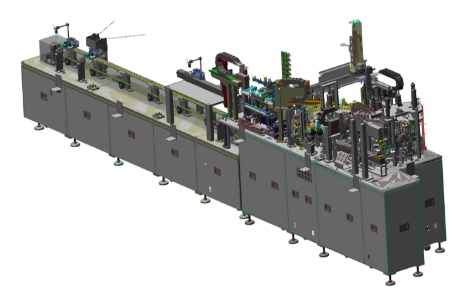

USB Charger Auto-Assembly

Equipment for Automotive

-

Specification

- - Equipment T/Time : 10sec/unit

- - Utilization : 95% or over

- - Operator : 1person

- - models available : 14models

-

-

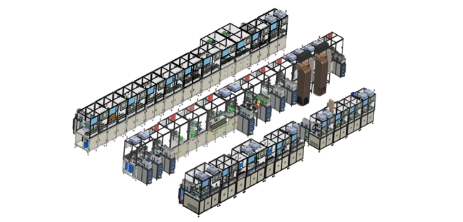

Cooling Fin Auto-assembly Equipment for Automotive

-

Specification

- - Equipment T/Time : 18sec/unit

- - Utilization : 95% or over

- - Operator : 1person

- - Models available : Multi

※ Inspection: flatness 9points, Gauge 1point

-

-

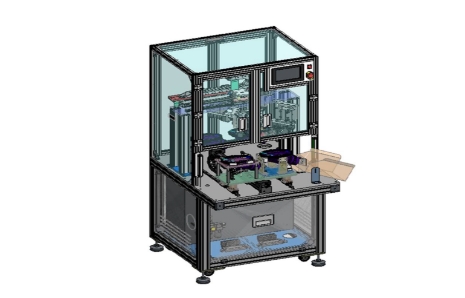

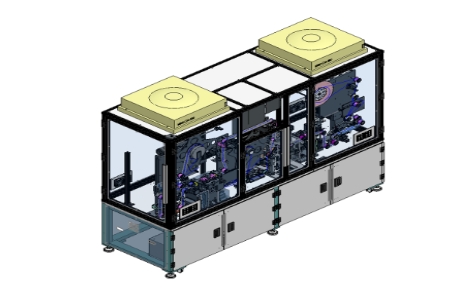

Index type parts

assembly Equipment

-

Applicable technology

- - Adhesion Technology of Insulated Tape

- - Type welding technology

- - Label Bonding technology

- - Characteristic check

-

-

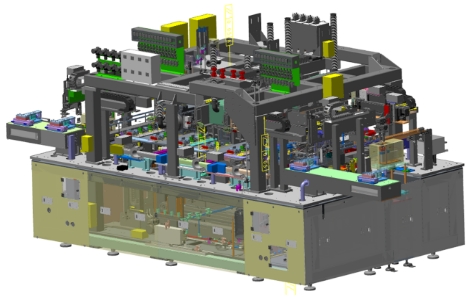

Medical device Assembly Equipment

-

Specification

- - Equipment T/Time : 8sec/Unit

- - Utilization : 90% or Over

- - Operator : 6 persons

-

Stand-alone on-demand equipment

-

Stand-alone type parts assembler

-

Specification

- - Equipment T/Time : 20sec/unit

(Depending on operating conditions) - - Utilization : 95% or over

- - Operator : 1person

- - Models available : Customize

- - Equipment T/Time : 20sec/unit

※ Create an optimal design for the desired job specifications

-

-

Robot utilized Image Processing Inspection

-

Specification

- - Multi-joint robot complex image tester

- - Inspection : dimension, shape, color, print, surface

(check by vision system) - - Models available : Customize

※ Point : Existing fixed-direction testing uses multi-joint robots to change direction according to product and inspection content Rapid response to changes in inspection targets and contents (For Smart Factory)

-

-

Automatic Loader of Finished Goods

-

Specification

- - Equipment T/Time : 5sec/unit

- - Utilization : 95% or over

- - Operator : 1person

- - Models available : Customize

-

※ Point

- - Flexible products loadable

- - Applying Equipment and soft applications capable of producing multiple varieties (10types)

- - Equipment lay-out considers operator’s movement

- - Composition of equipment with smooth communication with previous one

-

-

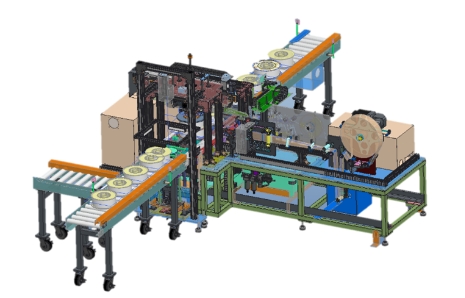

Automatic Packing Machine of Finished Goods

-

Specification

- - Equipment T/Time : 7sec (Depending on operating conditions)

- - Utilization : 95% or over

- - Models available : Plastic Spool Wire Basket

- - Operator : 1person

※ Can be added to the conveyor of the current manufacturing line

※ Applied product

-

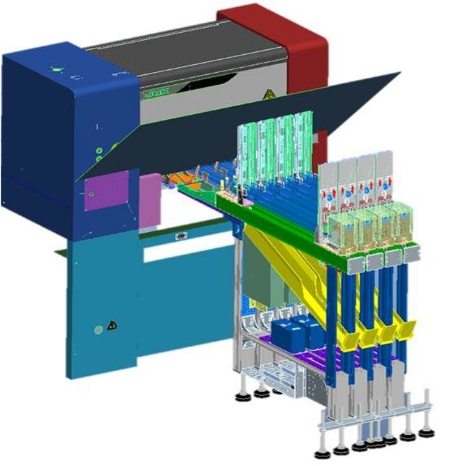

Odd-shape Parts Feeder for High-Speed Mounting

-

-

고속 실장용 이형 부품 Feeder NO. Items Spec 1 Lane Number 4 Lanes 2 Lane Pitch 51mm 3 Supply Speed Over 20pcs/Min (Target Over 30pcs) 4 Part 4Kinds 5 Setting JM-10 Rear Side 6 Pick-up Sensor ○ 7 Supply Rate Over 99.99% 8 Accuracy Pick Position X,YZ : Under±0.5mm 9 Height Adjust Height : 896mm±25mm 10 Equipment Size 740mm×1,210mm×960mm 11 Weight Under 300kg

(Depend on Supply Bowl Size)12 Use Condition Temperature : 10~35℃

Humidity : 30~80%RH

Safekeeping Temp : -15~70℃13 Air Supply 0.5Mpa

Odd-shape Parts Stick Feeder for High-Speed Mounting

-

-

고속 실장용 이형 부품 Stick Feeder NO. Items Spec 1 Part Size Width : 7~25mm

Length : 7~33.5mm

Height : (Include Lead)

: 7~28mm2 Part Weight Under 40g/pc 3 Stick Size Width : 10~25mm

Height : 10~33mm

Length : 500~600mm4 Stick Weight Under 400g (Include Parts) 5 Stick Type Plural Lead 6 Supply Speed 2Lanes/machine 7 Storage stick number 10sticks/lane 8 Supply Speed 1.5Sec/pc 9 Supply to Pick-up Position

Part sensor at Pick-up

Stick ChangeAuto Supply

Auto Change10 Supply Rate ≥99.99% 11 Accuracy Pick Position X,Y,Z : Within±0.5mm 12 Mounter JM-10, JM-20 (L, XL size)

Secondary Battery Key Process Equipment

-

Aluminum Thin Film Forming Equipment

-

Specification

- - Equipment T/Time : 7sec/unit

- - Utilization : 99.9% or more

- - Operator : 1person

- - Shape : Cylindrical, Square

SIZE: 2000(D)x1100(W)x1800(H)

-

-

Assembly Equipment

-

Specification

- - Equipment T/Time : 7sec/unit

- - Utilization : 99.9% or more

- - Operator : 1person

- - Shape : Cylindrical, Square

SIZE : 6600(D)x1500(W)x1700(H)

-

-

Inject electrolytic liquid Equipment

-

Specification

- - Equipment T/Time : 7sec/unit

- - Utilization : 99.9% or more

- - Operator : 1person

- - Shape : Cylindrical, Square

SIZE : 6600(D)x1500(W)x1700(H)

-

-

Non-woven fabric joint Equipment

-

Specification

- - Equipment T/Time : 0.3sec/unit

- - Utilization : 99.9% or more

- - Operator : 1person

- - Shape : Cylindrical, Square

※ Applicable to other products

SIZE : 750(D)x2300(W)x2000(H)

-